Membrane technology has become a dignified separation technology over the past decennia. The main force of membrane technology is the fact that it works without the addition of chemicals, with a relatively low energy use and easy and well-arranged process conductions.

Membrane technology is a generic term for a number of different, very characteristic separation processes. These processes are of the same kind, because in each of them a membrane is used. Membranes are used more and more often for the creation of process water from groundwater, surface water or wastewater. Membranes are now competitive for conventional techniques. The membrane separation process is based on the presence of semi permeable membranes.

The principle is quite simple: the membrane acts as a very specific filter that will let water flow through, while it catches suspended solids and other substances.

| Advantages and Features: |

- Non Thermal

- No Phase Change

- No Chemical Reaction

- Simple in Concept and Operation

- Modular and Easy to Scale-up

- Low Energy Consumption

- Environmental Friendly

- Recovery and Reuse of Byproducts

- Permit Drastic Improvements in Manufacturing and Processing

|

- Substantial Reduction in Equipment-size

- Provide Cheaper and Sustainable Technical Solutions

- High Quality of Final Products

- No Moving Parts

- Operational Flexibility

- Portability (where required)

- Flexibility for Automation and Remote Control

|

|

| |

|

|

| Application UF: |

- Degreasing Processes

- Metal Particle Recovery

- Metal Plating Wastewater Treatment

- Removal of Non-Toxic degradable pollutants such as

proteins and other macromolecular compounds and toxic non-degradable components, e.g. dyes and paints, with molecular weights greater than 1000

|

- Tertiary Treatment of the Effluent from Activated Sludge Process

- Segregation of Oil/Water Emulsions

- Separation of Heavy Metals after Complexation or Precipitation

- Pretreatment step prior to RO and Ion Exchang

|

|

| |

|

|

| Application RO: |

- Desalination

- Final Removal of Toxic Components

- Degradable Components, if biological treatment is not possible

- Post Treatment of the permeate from Ion Exchange and GAC Adsorption.

|

|

| |

|

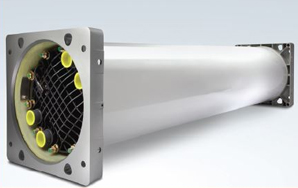

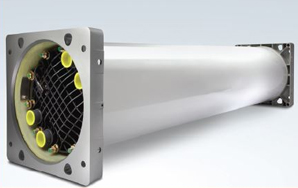

| Application of EDI: |

| EDI is useful for any application that requires constant and economic removal of water impurities without using dangerous chemical. Some examples are: |

- Reuse of residual water in food and beverages industry

- Chemical production

- Biotechnology

- Electronics

- Cosmetic

- Laboratories

- Pharmaceutical industry

- Boiler Feed Water

- Reduction of ionizable SiO2 and TOC

|

|

| |

|

| Advantages of EDI |

As a substitute for the more traditional ion-exchange process, EDI brings advances in both energy and operating expenses to the high purity water treatment train. By eliminating the periodic regeneration requirement of ion exchange resin, environmental benefits are also realized by avoiding the handling and processing of acid and caustic chemicals brought to the site.

Some of the advantages of the EDI as opposed to the conventional systems of ionic interchange are: |

- Simple and continuous operation

- Chemicals for regeneration completely eliminated

- Cost effective operation and maintenance

- Low power consumption

- Non pollution, safety and reliability

- It requires very few automatic valves or complex control sequences that need supervision by an operator

- It requires little space

- It produces high pure water in a constant flow

- It provides complete removal of dissolved inorganic particles

- In combination with reverse osmosis pre-treatment, it removes more than 99.9% of ions from the water

|

|